DESCRIPTION

- The water yield and recovery rate of each one are all designed by dedicated membrane software according to the local water quality, please do not increase the water yield and recovery rate optionally, otherwise, the membrane will be damaged badly.

- The information and data provided by the instructions are accurate and useful, but because users’ working methods and working conditions are not in our control, so the information and data being provided are only for reference, not for Guarantee Value.

- Because there is many differences between the specific configuration of the Reverse Osmosis and the requirement of the water-yield flux rate, influent quality, and effluent quality, our company will not further notice if the user’s actual configuration is different from the instructions.

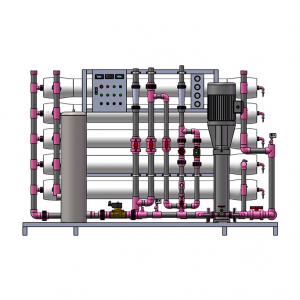

REVERSE OSMOSIS SYSTEM

The 1000 liters per hour reverse osmosis system water treatment package is suitable for applications requiring depth filtering.

More than 99% of all microorganisms, pyrogens, particulates, organics with a molecular weight greater than 300, and up to 95% of all dissolved inorganic contaminants from the feed water are removed.

Specifications

- Capacity: 6000 GPD

- RO Membrane: 4 pcs

- RO Pump: 3HP

- Voltage/Hertz: 110V or 220V / 50Hz or 60Hz / Single-phase or three-phase

- Pipe Size: 3/4″ Feed, 1/2″ Permeate, 1/2″ Concentrate, 1/2″ Flush (BSP thread)

Features

- Sediment Filter: 5 Micron Sediment Filter that removes sediments and protects the system.

- High-Pressure Pump: 1HP Motor Vertical Multi-Stage Pump with a flow rate of 1080 Liters/H. High-quality stainless steel Shimge Pump for long-life usage.

- RO Membrane: One of the industry’s leading brackish water RO elements – Vontron-4040.

- Membrane Housing: 4″ x 40″ Stainless Steel Housing with 300PSI maximum operating pressure.

- Pressure Gauges: Glycerin Filled Gauges for monitoring the system’s operating pressure and per liter operating pressures.

- Low-Pressure Switch: Safety device to protect the pump from running dry when there is insufficient water feed pressure.

- Solenoid Valves: To assist with the on/off functionality of the system and automatic membrane flush.

- Flow Meters: One Product and One Waste Flow Meters – Enables the operator to actually adjust the product to waste ratio and monitor the system’s performance.

- Regulator Valve: One Stainless Steel ANSI 316 Needle Valve – regulates the product to waste ratio (system’s recovery).

- Micro-Computer Controller: A specialized controller designed by Puritech for commercial systems with automatic controls and TDS monitors.

Operating Parameters

- 180 PSI | Max. Feed TDS | 1000 ppm

- Normal Salt Rejection: 99% | Max. Feed Hardness | 15 ppm

- Minimum Salt Rejection: 96% | Feed pH Range | 3.0 – 10.0 ppm

- Operating Temperature: 20 ̊C – 45 ̊C | Free Residual Chlorine | 0.1 ppm

- Minimum Feed Pressure: 1.5Kg | Recovery Rate | 60% – 75%

FEED PUMP

Horizontal Multi-Stage Centrifugal Pump (CHT2)

Applications

CHT series are mini horizontal centrifugal pumps, have a wide application in domestic water supply industry and construction. They are used for:

- Air-conditioning systems

- Cooling Systems

- Industrial cleaning, conveyance and circulation of liquid. Water treatment (Water Purification)

- Domestic water supply boosting

Other Special usages - Working conditions

- Diluted, clean, non-flammable, and non-explosive liquids

- Liquid without solid grain or fibers

- Liquid Temperature:

- Low temperature: -20 ̊C ~ +70 ̊C

- Standard temperature: +15 ̊C ~ +70 ̊C

- High temperature: +70 ̊C ~ +104 ̊C

- Max. environmental temperature: 50 ̊C

- Max. operating pressure: 10 bar

- Max. Suction pressure is limited by max. operating pressure

Motor

- 2-pole induction motor;

- Three-phase: 220/380V/50Hz Single-phase with input thermal protector Insulation class: F

- Protection: IP55

- Continuous duty

DOSING PUMP

ALLEDOSIEREN®

Specifications

- Flow: 0.48 ~ 15.20 L/h

- Pressure: 8.2 ~ 1.8 Bar

Features

- LCD display

- Adjust the flow by key

- Cycle timer

- Frequency or percentage model

- Optional automatic control by an external signal

DESCRIPTION

- The water yield and recovery rate of each one are all designed by dedicated membrane software according to the local water quality, please do not increase the water yield and recovery rate optionally, otherwise, the membrane will be damaged badly.

- The information and data provided by the instructions are accurate and useful, but because users’ working methods and working conditions are not in our control, so the information and data being provided are only for reference, not for Guarantee Value.

- Because there is many differences between the specific configuration of the Reverse Osmosis and the requirement of the water-yield flux rate, influent quality, and effluent quality, our company will not further notice if the user’s actual configuration is different from the instructions.

REVERSE OSMOSIS SYSTEM

The 1000 litters per hour reverse osmosis system water treatment package is suitable for applications requiring depth filtering.

More than 99% of all microorganisms, pyrogens, particulates, organics with a molecular weight greater than 300, and up to 95% of all dissolved inorganic contaminants from the feed water are removed.

Specifications

- Capacity: 6000 GPD

- RO Membrane: 4 pcs

- RO Pump: 3HP

- Voltage/Hertz: 110V or 220V / 50Hz or 60Hz / Single-phase or three-phase

- Pipe Size: 3/4″ Feed, 1/2″ Permeate, 1/2″ Concentrate, 1/2″ Flush (BSP thread)

Features

- Sediment Filter: 5 Micron Sediment Filter that removes sediments and protects the system.

- High-Pressure Pump: 1HP Motor Vertical Multi-Stage Pump with a flow rate of 1080 Liters/H. High-quality stainless steel Shimge Pump for long-life usage.

- RO Membrane: One of the industry’s leading brackish water RO elements – Vontron-4040.

- Membrane Housing: 4″ x 40″ Stainless Steel Housing with 300PSI maximum operating pressure.

- Pressure Gauges: Glycerine Filled Gauges for monitoring the system’s operating pressure and per liter operating pressures.

- Low-Pressure Switch: Safety device to protect the pump from running dry when there is insufficient water feed pressure.

- Solenoid Valves: To assist with the on/off functionality of the system and automatic membrane flush.

- Flow Meters: One Product and One Waste Flow Meters – Enables the operator to actually adjust the product to waste ratio and monitor the system’s performance.

- Regulator Valve: One Stainless Steel ANSI 316 Needle Valve – regulates the product to waste ratio (system’s recovery).

- Micro-Computer Controller: A specialized controller designed for commercial systems with automatic controls and TDS monitors.

Operating Parameters

- 180 PSI | Max. Feed TDS | 1000 ppm

- Normal Salt Rejection: 99% | Max. Feed Hardness | 15 ppm

- Minimum Salt Rejection: 96% | Feed pH Range | 3.0 – 10.0 ppm

- Operating Temperature: 20 ̊C – 45 ̊C | Free Residual Chlorine | 0.1 ppm

- Minimum Feed Pressure: 1.5Kg | Recovery Rate | 60% – 75%

FEED PUMP

Horizontal Multi-Stage Centrifugal Pump (CHT2)

Applications

CHT series are mini horizontal centrifugal pumps, have a wide application in domestic water supply industry and construction. They are used for:

- Air-conditioning systems

- Cooling Systems

- Industrial cleaning, conveyance and circulation of liquid. Water treatment (Water Purification)

- Domestic water supply boosting

Other Special usages - Working conditions

- Diluted, clean, non-flammable, and non-explosive liquids

- Liquid without solid grain or fibers

- Liquid Temperature:

- Low temperature: -20 ̊C ~ +70 ̊C

- Standard temperature: +15 ̊C ~ +70 ̊C

- High temperature: +70 ̊C ~ +104 ̊C

- Max. environmental temperature: 50 ̊C

- Max. operating pressure: 10 bar

- Max. Suction pressure is limited by max. operating pressure

Motor

- 2-pole induction motor;

- Three-phase: 220/380V/50Hz Single-phase with input thermal protector Insulation class: F

- Protection: IP55

- Continuous duty

DOSING PUMP

ALLEDOSIEREN®

Specifications

- Flow: 0.48 ~ 15.20 L/h

- Pressure: 8.2 ~ 1.8 Bar

Features

- LCD display

- Adjust the flow by key

- Cycle timer

- Frequency or percentage model

- Optional automatic control by an external signal

Reviews

There are no reviews yet.